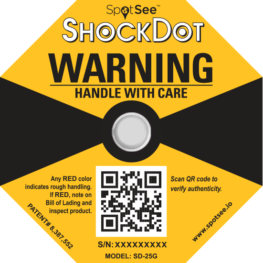

ShockDot Impact Indicators

Are a cost-effective solution that detects the mishandling of products and packages during shipment. Alerting handlers that a package is being monitored and requires extra care will ultimately reduce damage related costs. ShockDot impact indicators are omnidirectional impact indicators.

Selecting the most suitable ShockDot impact indicators

Available in five sensitivities, as indicated by the five different colours – simply match the sensitivity of the ShockDot impact indicator to the level of impact the product and packaging can withstand based on any non operating shock specifications that the product may have or select the ShockDot impact indicator based on the mass and size of your shipment from our ShockDot Selection Guide below.

If a package has not been mishandled, the circular indicator in the centre of the ShockDot will remain white. If the package has been dropped, the indicator will show full or partial red colouration. Any red in the ShockDot impact indicator window alerts receivers to inspect the package for any potential damage.

ShockDot visually deters and detect mishandling

The ShockDot impact indicators mount to the exterior of the packaging of a shipment and visually alerts everyone involved in the handling of the package that additional care is required. If mishandling occurs during the shipment and handling cycle, the ShockDot serves as a permanent record of mishandling.

Economical solution to reduce your damage related costs

ShockDot impact indicators offer an economical solution to prevent damage during product transit.

Indicate when mishandling has occurred with ShockDot impact indicators

The ShockDot impact indicators are not indicators of damage, they are an indicator of mishandling. If a shipment arrives at a destination with an activated ShockDot, the receiver should immediately note any visible damage to the shipment, open the package and inspect for any damage to the goods.

Using ShockDot impact indicators to determine if any damage to the product may have occurred requires in house drop testing to ascertain the ShockDot which is most suitable. This may lead to reducing the number of inspections that may have to be performed by the end user.

Applications

- Energy and Utilities

- Furniture and Fixtures

- Auto and Truck Parts

- Metal Fabrication

- Consumer Electronics

- Telecommunications Equipment

- Network Equipment

- IT Hardware

- High Tech Equipment

- Instrument Panels

- Logistics & Transport

- Packaging/Crating

- Medical Supplies

- Medical Devices

- Aerospace Components

- Defense Components

- Small Distribution Transformers

- Appliances

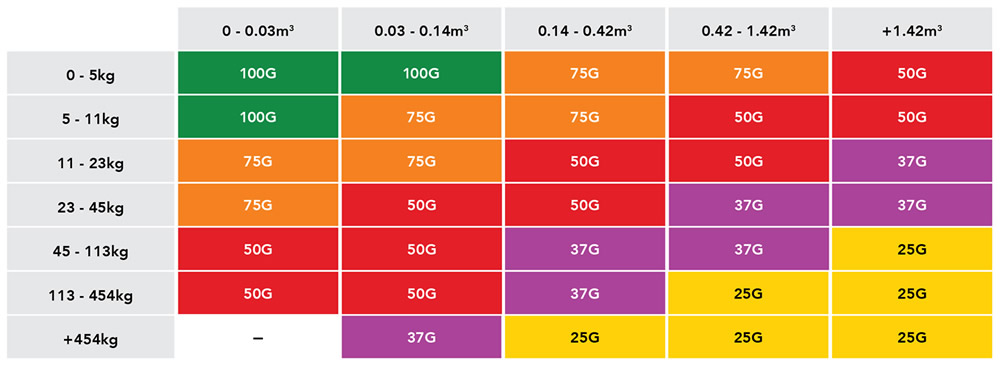

ShockDot Selection Guide

There are two things you need to know to begin selecting a ShockDot impact indicator sensitivity: shipment size (m³) and weight (kgs).

The selection guide should always be used as a starting point only. The ShockDot that will be best suited to your application will also take into account product fragility and packaging.

A Complete ShockDot Impact Indicator Program

The ShockWatch Program is more than just an impact indicator. A key element in the success of using ShockDot Labels are the companion tools. When used in conjunction with companion labels, alert tape and communication tools, ShockDot impact indicators become a highly effective damage reduction and prevention program.

Implementation of this program provides psychological reinforcement of proper handling procedures and changes the behaviour of material handlers. It provides a highly visible deterrent to mishandling throughout the supply chain and encourages package handlers to be more conscious of their behaviour and surroundings.

Success of the ShockWatch Program is measured by a reduction in damage. Preventing mishandling is the key to damage reduction.

Download our ShockWatch Impact Indicators Implementation Guide

Contact us for further information on the ShockWatch Program or if you would like any information on ShockDot Activation Curves.

Optional Companion Labels and Alert Tape are recommended for use with the ShockDot as additional tools that increase the visibility or the handling requirements of your package. The ShockDot is applied to the Companion Label and the Companion Label is applied to the shipment.

(see Accessories below)

Benefits

- Acts as a visual deterrent to improper handling

- Reduces mishandling through awareness

- Provides indisputable evidence of mishandling

- Alerts recipient to inspect contents before acceptance

- Verify authenticity of the ShockDot by scanning the QR code and entering in the serial number

- Promotes chain of accountability for all product handling

- Confirms effectiveness of packaging

- Helps identify trouble spots in the supply chain from production to transportation and storage

- Helps increase the quality of product from dock to dock