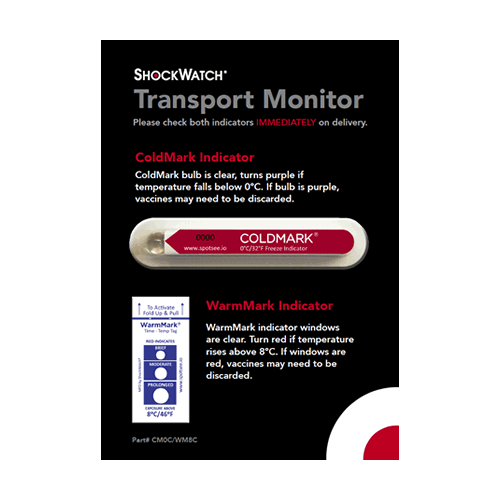

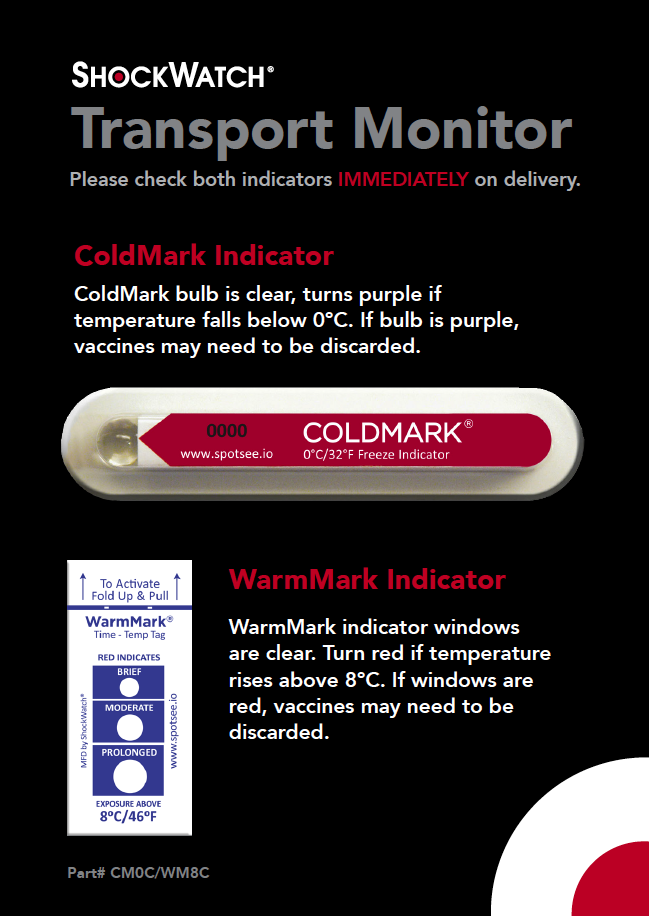

The Cold Chain Transport Monitor temperature indicators provide a reliable, cost effective alternative for monitoring products through the cold chain process, especially in the last mile. Packaged as a single use device on a card, the solution combines the benefits of both an ascending time temperature indicator, WarmMark, and a descending indicator, ColdMark, to give users irreversible evidence of unacceptable temperature exposure, helping to maintain cold chain accountability and product quality.

Cold Chain Transport Monitor can be used in the medical, food logistics and chemical industries to ensure supply chain transparency and temperature accuracy. The Transport Monitor card give clear instructions to the end user whether a cold chain breach has compromised the efficacy of the product.

Cold Chain Transport Monitor can be made to a combination of any of our available temperature indicators.

COLDMARK is available in the following temperature thresholds:

-3°C | 0°C | 2°C | 5°C | 10°C

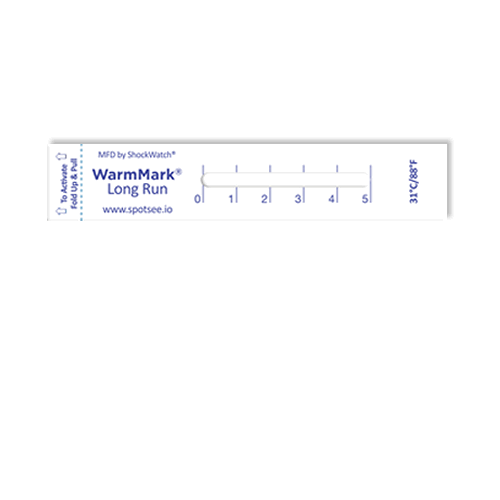

WARMMARK is available in the following temperature thresholds:

-18°C | 0°C | 5°C | 8°C | 10°C | 20°C | 25°C | 30°C | 37°C

HOW IT WORKS

- Mount the ColdMark and WarmMark temperature indicators on the spaces provided.

- Peel the paper layer to expose the adhesive on the back of the card

- Place the card inside the box as close to the goods as possible.

- Immediately check both indicators on delivery.

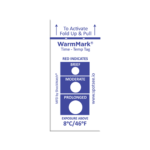

- If the ColdMark bulb has turned violet and/or if any of the WarmMark indicator windows have turned red you may need to discard the products.

FEATURES

- Freeze Indicator

- Warm Indicator

- Field armable with pull tab

- Brief, moderate, prolonged exposure times

APPLICATIONS

- Floral

- Specimens

- Chocolate

- Tissue samples

- Pharmaceutical

- Meal delivery

- Raw and cooked meats

- Chemicals